Welchen Einfluss haben verschiedene Korundstrahl- und Alterungsmethoden auf Biegefestigkeit und Phasenzusammensetzung von Zirkonoxid der 1. und 2. Generation? Im Rahmen einer Studie an der LMU München konnte diese Fragestellung näher beleuchtet werden.

Matthias Kelch, München

Metallfreie prothetische Versorgungen sind zu einem essenziellen Bestandteil moderner Behandlungskonzepte geworden. Die rapide Entwicklung verschiedener Zirkonoxide erfordert fundierte Kenntnisse über die Materialeigenschaften und deren Verarbeitungsprozesse.

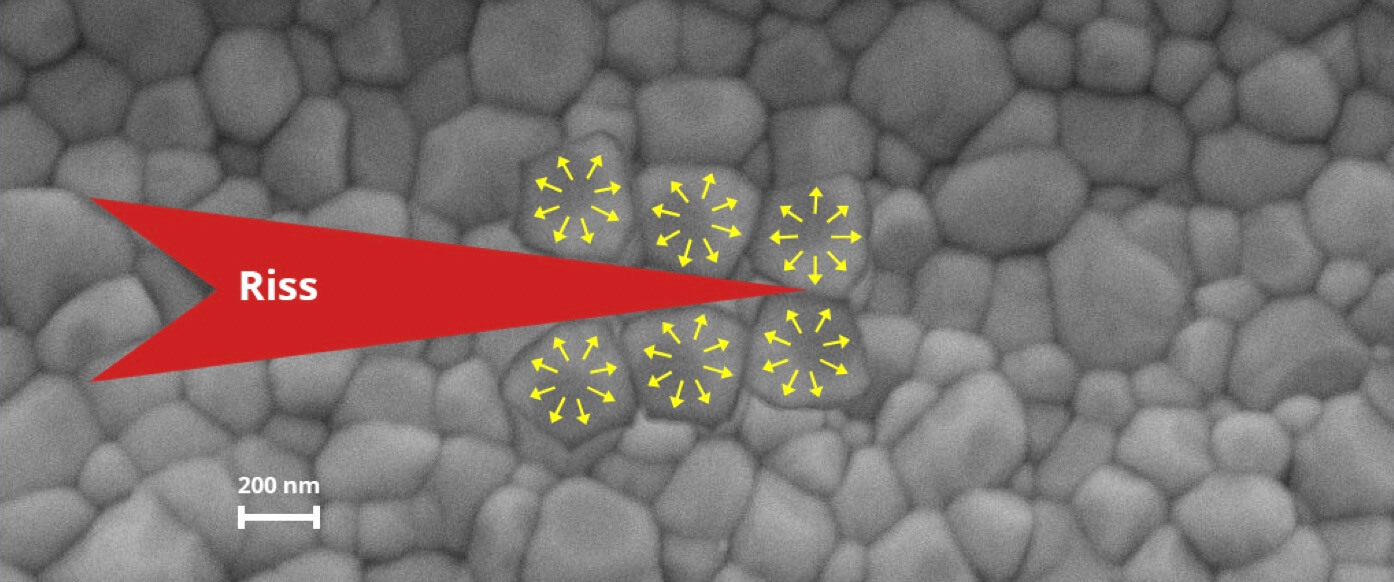

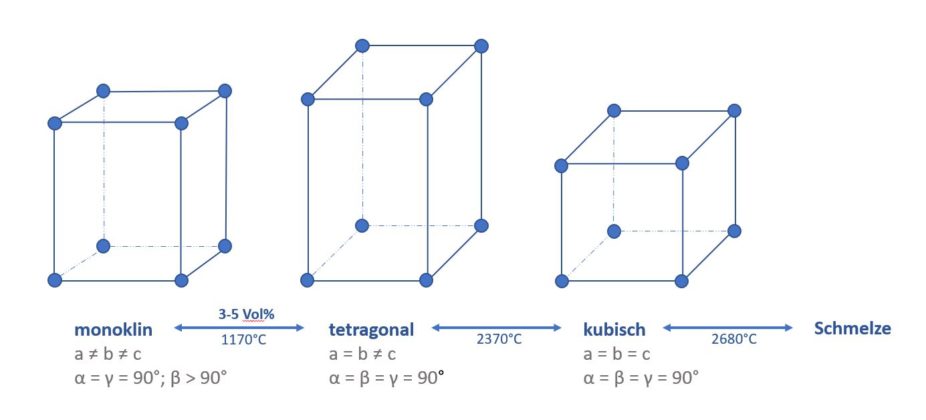

Zirkonoxid liegt es in drei verschiedenen Phasen vor. Der Anteil der Phasen bestimmt jeweils die Eigenschaften des Materials. Bei der Bearbeitung einer Zirkonoxidoberfläche spielt das Verhalten der Phasenzusammensetzung bei Stresseinwirkung eine zentrale Rolle. Hierbei kann es zu einer Umwandlung von der tetragonalen in die monokline Phase kommen. Dieser Vorgang ist mit einer Volumenzunahme von 3-5% verbunden.

Verschiedene Phasen von Zirkonoxid:

- monoklin

- tetragonal

- kubisch

Temperaturabhängige Kristallphasen von Zirkonoxid. Volumenzunahme von 3-5% beim Übergang von der tetragonalen in die monokline Phase. [Stawarczyk B, Keul C, Eichberger M, Figge D, Edelhoff D, Lümkemann N: Werkstoffkunde-Update: Zirkonoxid und seine Generationen – von verblendet bis monolithisch. Quintessenz Zahntechnik 2016, 42(6):740-765].

Welche Effekte durch dieses Verhalten provoziert werden, wird in der Literatur kontrovers diskutiert. Einerseits soll Risswachstum unterbunden werden und die entstehende Kompressionsschicht zu einer Festigkeitssteigerung führen. Andererseits wurden aber auch festigkeitsmindernde Effekte durch entstehende Mikrorisse beschrieben.

Die Vorbehandlung der Oberfläche durch Korundstrahlen …

- beispielsweise vor dem Verblenden oder

- im Rahmen der Befestigung

… kann eine potenzielle Ursache für eine Phasenumwandlung darstellen. Warum hier vor allem die Alterung eine tragende Rolle spielt, verdeutlicht die nachfolgend zusammengefasste In-vitro Studie der LMU München.

Ziel der Untersuchung

Ziel der Untersuchung war es, den Einfluss verschiedener Korundstrahl- und Alterungsmethoden auf die Biegefestigkeit von 3Y-TZP0.25 zu analysieren und den Effekt einer möglicherweise entstandenen monoklinen Phase zu untersuchen. Des Weiteren wurde der Einfluss von Korngröße und appliziertem Druck auf die Entstehung monokliner Phasen bei 3Y-TZP0.25 und 3Y-TZP0.05 untersucht.

Material und Methoden

Untersuchung der Biegefestigkeit

Für den 3-Punkt-Biegeversuch wurden insgesamt 180 Prüfkörper der Materialgruppe 3Y-TZP0.25 (Ceramill Zi, AmannGirrbach, Österreich) hergestellt. Diese wurden im ersten Schritt nach dem Zufallsprinzip in vier Vorbehandlungsgruppen (n=45) unterteilt:

- Korundstrahlen mit 50 µm Aluminiumoxid-Pulver (Hasenfratz, Deutschland)

- Korundstrahlen mit 105 µm Aluminiumoxid-Pulver (Hasenfratz)

- Korundstrahlen mit 30 µm SiO2-beschichtetem Aluminiumoxid-Pulver (Rocatec soft powder, 3M, Deutschland)

- Keine Vorbehandlung

Vorrichtung zur Sicherung konstanter Bedingungen während des Korundstrahlens mit einem festen Winkel von 45° und einem gleichbleibenden Abstand der Düse von 10 mm.

Analyse kristalliner Strukturen

Zur Analyse der kristallinen Phasenstruktur wurden weitere Prüfkörper aus 3Y-TZP0.25 (Ceramill Zi, AmannGirrbach, n=12) und 3Y-TZP0.05 (Ceramill Zolid, Amann Girrbach, n=8) hergestellt. Diese wurden entsprechend den bereits beschriebenen Methoden vorbehandelt und im Autoklaven gealtert. Um einen etwaigen Einfluss des Abstrahldrucks zu untersuchen, erfolgte das Korundstrahlen mit 50 µm und 105 µm Aluminiumoxidpulver mit verschiedenen Strahldruckparametern von 0.05, 0.25 und 0.4 MPa.Um mögliche Veränderungen der Phasenstruktur von 3Y-TZP0.25 nach einer 5-jährigen Trockenlagerung bei Raumtemperatur (23°C) zu zeigen, wurden auch die Bruchstücke der Prüfkörper aus dem 3-Punkt-Biegeversuch analysiert. Der Nachweis stattgefundener Phasenumwandlung erfolgte mit Hilfe eines Raman-Spektroskops (inVia Qontor, Renishaw plc, UK).

Ergebnisse

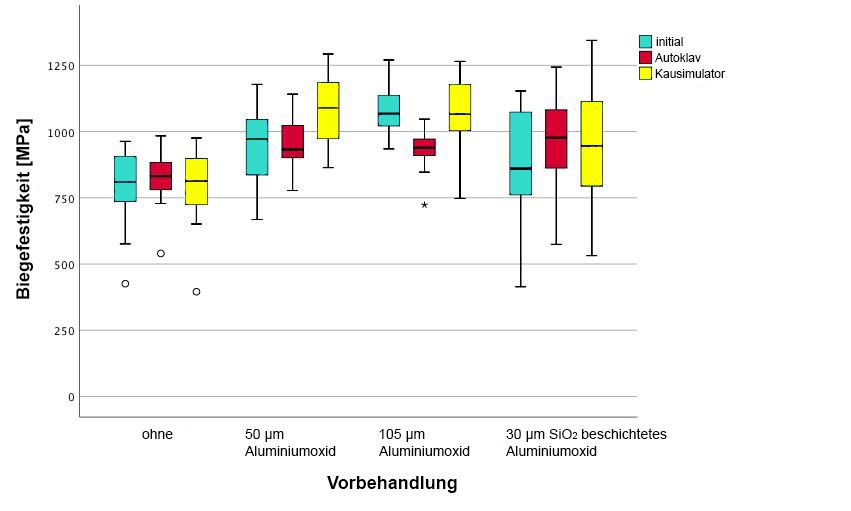

Die mechanische Vorbehandlung durch Korundstrahlen erhöhte die Biegefestigkeit von nicht-gealtertem 3Y-TZP0.25 mit steigender Korngröße. Die Alterung von Prüfkörpern im Autoklaven und im Kausimulator, welche mit 50 und 105 µm Aluminiumoxid-Pulver korundgestrahlt wurden, hatte mehr Einfluss auf ihre Biegefestigkeit als bei jenen, die zuvor mit 30 µm SiO2-beschichtetem Aluminiumoxid-Pulver korundgestrahlt wurden. Größere Korundpartikel und steigender Strahldruck erhöhten den monoklinen Phasenanteil. Alle Vorbehandlungsgruppen zeigten einen höheren monoklinen Phasenanteil nach Alterung im Autoklaven und/oder 5-jähriger Alterung bei Raumtemperatur. Ausnahme sind mit 30 µm SiO2-beschichtetem Aluminiumoxid-Pulver korundgestrahlten Prüfkörpern.

Grafische Darstellung der Ergebnisse

Vorbehandlung / Alterung Zirkonoxid: Schlussfolgerung

Das Korundstrahlen einer Zirkonoxid-Oberfläche mit 30 µm SiO2-beschichtetem Aluminiumoxid-Pulver kann als Vorbehandlungsmethode empfohlen werden. Dies ist unabhängig davon, ob es sich um 3Y-TZP0.25 oder 3Y-TZP0.05 handelt. Bei Vorbehandlung mittels Aluminiumoxid sollte grundsätzlich auf einen möglichst geringen Strahldruck geachtet werden.