Das Verblenden von Zirkonoxid-Restaurationen ist Alltag in vielen Dentallaboren. Doch welchen Einfluss auf Verblendkeramiken hat eine unterschiedliche Anzahl an Bränden auf die thermischen und mechanischen Eigenschaften der Materialien? Innerhalb einer Studie an der LMU München wurde dies nähergehender untersucht.

Bild (v.o.n.u.): 2-, 4-, 6-, 8- und 10-mal gebrannte Prüfkörper mit zunehmend erkennbarer Kantenabrundung.

Justine Hensel, München

Vollkeramische Restaurationen haben sich bewährt und werden immer beliebter. Sie stellen eine mechanisch zuverlässige Restauration mit hoher Stabilität und hervorragender Biokompatibilität dar. Zudem ergeben sich aus ästhetischer Sicht viele Vorteile gegenüber metallkeramischen Restaurationen. Zirkonoxid als Dentalkeramik mit der höchsten Biegefestigkeit (1. und 2. Generation = 900 – 1500 MPa) und Bruchzähigkeit wird gerne als Gerüstwerkstoff eingesetzt. Allerdings erscheint dieses Zirkonoxid aufgrund seiner kristallinen Struktur opak und wird insbesondere im Frontzahnbereich nicht monolithisch angewandt. Wie von metallkeramischen Restaurationen bekannt, erfolgt daher ein Verblenden. Allerdings wurden Frakturen innerhalb der Verblendkeramik – das „Chipping“ – häufig als Hauptfaktor für das Versagen von Restaurationen beobachtet.

Von großer Bedeutung scheinen interne Spannungen zu sein, denn diese kann Zirkonoxid als sprödes Material weniger gut kompensieren als die klassische Form von Metallgerüsten. Daher ist es wichtig, den Gesamtspannungszustand der Restauration so gering wie möglich zu halten. Bei diesen Eigenspannungen handelt es sich in erster Linie um thermische Spannungen, die während der Herstellung der Restauration entstehen und beim Abkühlen im Werkstoff „gespeichert“ werden. Folglich ist anzunehmen, dass gerade die thermischen Eigenschaften der Materialien eine entscheidende Rolle spielen.

Ziel der Untersuchung

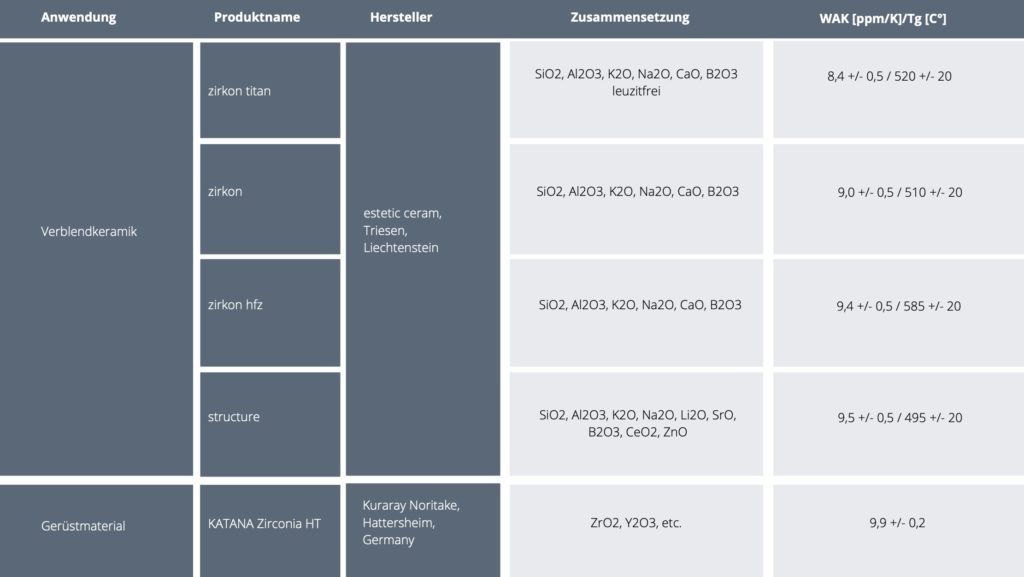

Beim Verblenden von Vollkeramik-Restaurationen sind in der Regel mehrere Brennvorgänge notwendig, um Form sowie Farbe entsprechend anzupassen. Ziel der Untersuchung war es, den Einfluss einer unterschiedlichen Anzahl an Bränden auf die thermischen Eigenschaften der Materialien – Wärmeausdehnungskoeffizienten (WAK) und Glasübergangstemperatur (Tg) – sowie die Verbundfestigkeit zwischen Verblendung und Zirkonoxidgerüst zu analysieren. Dafür wurden vier Verblendkeramiken mit unterschiedlichen Eigenschaften verwendet, darunter eine, die für den Gebrauch auf Zirkonoxid und Titan vorgesehen und leuzitfrei ist. Leuzit wird Verblendkeramiken meist als kristalline Phase beigefügt, sodass der WAK gesteuert und an den WAK des Gerüstmaterials angepasst werden kann.

Getestete Materialien und deren Zusammensetzung sowie deren thermische Eigenschaften laut Herstellerangaben.

Material und Methoden

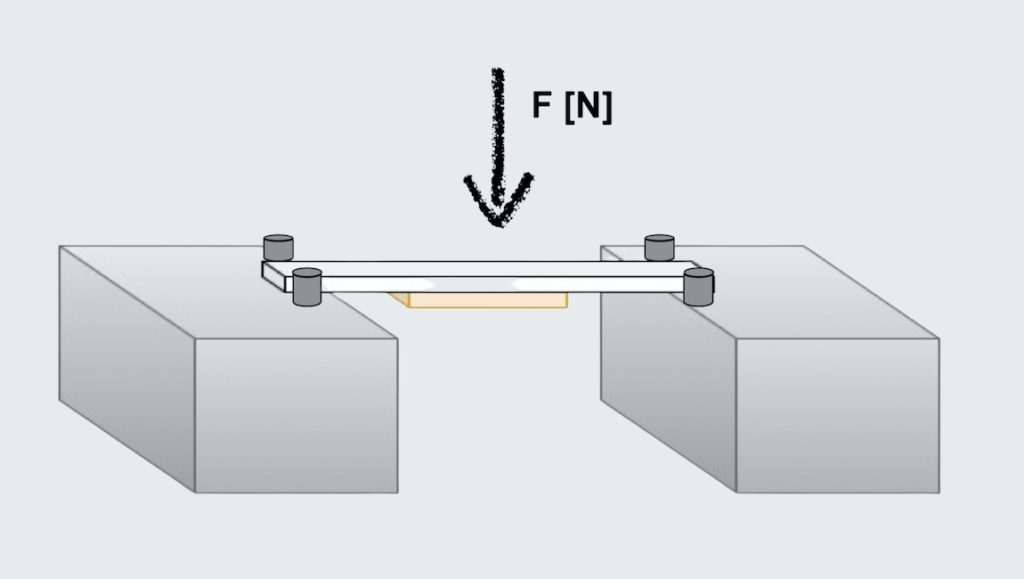

Die thermischen Eigenschaften (WAK und Tg) wurden jeweils nach 2, 4, 6, 8 und 10 Bänden untersucht. Auch bei dem Gerüstmaterial Zirkonoxid wurde der WAK gemessen. Die Messungen wurden mit einem Dilatometer durchgeführt. Die durch die Wärme verursachte Ausdehnung der Prüfkörper konnte durch Induktion registriert werden, indem der Messstab aus Quarzglas bewegt wurde. Die Haftfestigkeit ist mittels Rissbeginnprüfungen nach Schwickerath mit denselben Verblendkeramiken und Zirkonoxid vorgenommen worden. Das Keramikpulver wurde auf eine Fläche von 3 mm x 8 mm aufgetragen und gebrannt. Auch hier erfolgte ein 2-, 4-, 6-, 8- und 10-maliger Brand. Die Hälfte von den Prüfkörpern wurde im Thermocycler künstlich gealtert (5000 Zyklen, 5 °C/55 °C, 20 s). Im Anschluss ist die Haftfestigkeit geprüft worden.

Vereinfachte Darstellung der Prüfkörperhalterung einer die Universalmaschine für den 3-Punkt-Biegeversuch mit eingelegtem Prüfkörper

Ergebnisse

Thermische Eigenschaften

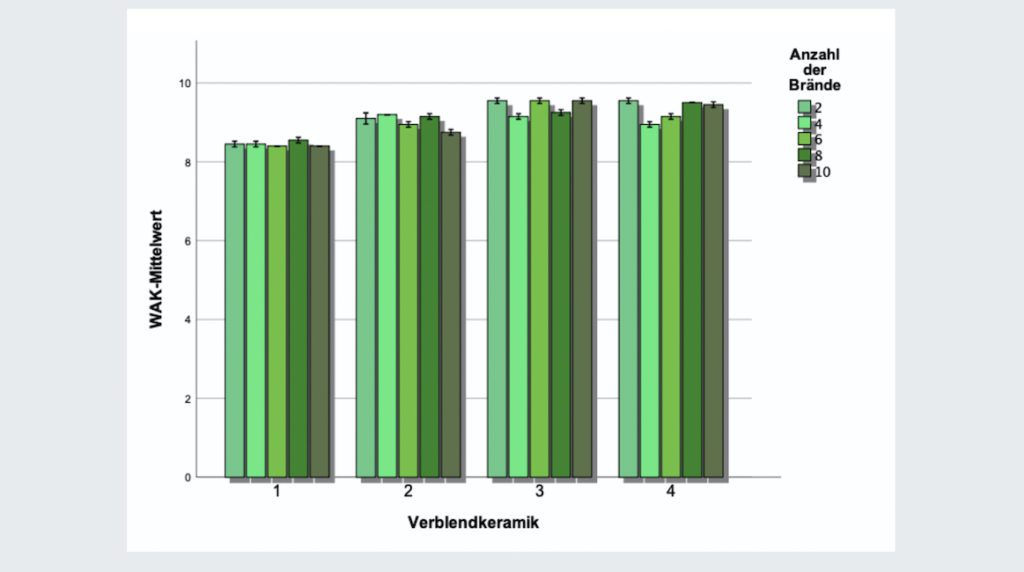

Die leuzitfreie Verblendkeramik (1) zeigte über die Brände hinweg nahezu konstante WAK-Werte. Bei den anderen Keramiken traten Schwankungen der Werte zwischen den Bränden auf. Die Tg wurde durch die Anzahl der Brände nicht beeinflusst. Es ist eine signifikante Korrelation zwischen CTE und Tg beobachtet worden.

WAK-Mittelwerte der jeweils getesteten vier Verblendkeramiken, wobei Verblendkeramik (1) leuzitfrei ist.

Verbundfestigkeit

Lediglich die Festigkeitswerte nach 2 und nach 10 Bränden unterschieden sich signifikant voneinander, wobei bei den Werten aller Verblendkeramiken zusammengenommen nach 10 Bränden etwas geringere Ergebnisse erzielt wurden. Die höchsten Festigkeitswerte wurden für die leuzitfreie Verblendkeramik (1) gemessen. Die künstliche Alterung durch das Thermocycling zeigte keinen Einfluss auf die Verbundfestigkeit zwischen Verblendung und Gerüst.

Die Ergebnisse wurden im Rahmen einer Publikation bei Dental Materials eingereicht.