Felix Schmeiser M.Eng, Munich

In addition to the general stress caused by the masticatory mechanism, splint materials must withstand forces of up to 770 N during malfunction of the masticatory system. Besides subtractive manufacturing with milling machines, 3D printing has already become widely established in modern dentistry. Due to the advantages in terms of material consumption, manufacturing time and associated costs compared to conventional and subtractive manufacturing, additive manufacturing already covers a large area within the manufacturing of splints.

In the literature, subtractive splint materials have prevailed over additive splint materials due to lower abrasion losses. However, promising insights into the influencing factors of additive manufacturing have been gained, resulting in steady progress in optimization. In addition, among other things, higher accuracy has been observed in the manufacture of dental restorations using additive manufacturing.

Milled and printed splints

Aim of this investigation

This investigation evaluated the influence of the manufacturing technology (milled vs. printed) of splint materials with respect to two-body wear. In addition to the quantitative evaluation of the results, microscopic images of all crowns were analyzed in order to incorporate qualitative evaluation principles.

Material and method

Investigation of two-body wear

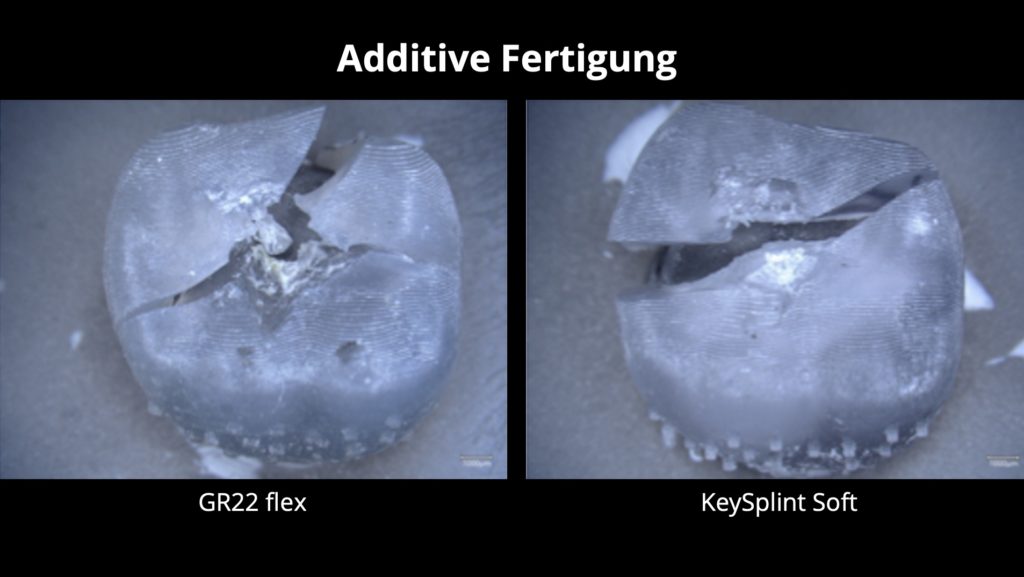

Crowns based on the geometry of a first mandibular molar were milled (Thermeo, pro3dure medical GmbH; CLEARsplint, Astron Dental) and printed (GR22 flex, pro3dure medical GmbH; KeySplint soft, Mycone Dental Supply, Co., Inc.). To compensate post-polymerization effects, 3D printing was performed exactly 7 days prior to chewing simulation.

Abutmenst as well as the inside of the crowns were air-abraded with aluminum powder with an mean grain size of 110 µm and a pressure of 1.5 bar. The crowns were bonded on the abutments.

The chewing simulation was performed under the following conditions:

- antagonists made from natural teeth

- number of chewing cycles = 120.000 x (app. 0.5 years in-vivo)

- force = 50 N

- lateral movement = 0.7 mm

- constant temperature (37 °C)

Microscopic examination and determination of abrasion loss

After chewing simulation, the crowns were evaluated under a digital light microscope to obtain a qualitative impression of the abrasion surfaces and then scanned with a laser scanner. If no breakout or fracture of the crown occurred, the digitized surface was evaluated using a matching software.

Vertical abrasion losses of the investigated splint materials

With regard to the investigations of the splint materials, no differences in the abrasion resistances were found. However, it has been shown that the milled crowns exhibit pure abrasion on the surface more frequently than the printed crowns. Related to this, in terms of damage patterns, milled crowns have a breakdown of the antagonist through the surface, but printed crowns have a fracture of the entire structure.

Manufacturing of splints: conclusion

Within this investigation the following conclusions can be made:

-

No significant differences were found in terms of material loss between all spint materials.2. Three-dimensionally printed splints showed more frequent fracture, while milled splints were more likely to show breakdown.