3D printed resin restorations … The ongoing innovations in the field of additive manufacturing are opening up further clinical applications in dentistry. The 3D printing technology now presents aesthetic tooth-coloured restorations that can be produced quickly and material-saving.

Valerie Lankes, LMU Munich

Leading dental printing technologies include photopolymerisation-based stereolithography (SLA) and digital light processing (DLP). This is preceded by computer aided design (CAD), the digital construction of a restoration with support structures and the positioning on the platform of the printer. Immediately after printing, post-processing follows, in which the printed objects are chemically or mechanically cleaned of excess unpolymerised resin. The subsequent post polymerisation manifests the material properties.

Nowadays, the additive manufacturing of long-term temporary restorations increasingly offers an alternative to conventional manufacturing due to improved material properties. But for a successful clinical use of fixed 3D-printed restorations, luting is a crucial factor. However, the low residual monomer content, high conversion rate and highly cross-linked density of carbon bonds can be a challenge for bonding to adhesive luting materials.

In vitro-study: Cleaning method and the mechanical pretreatment

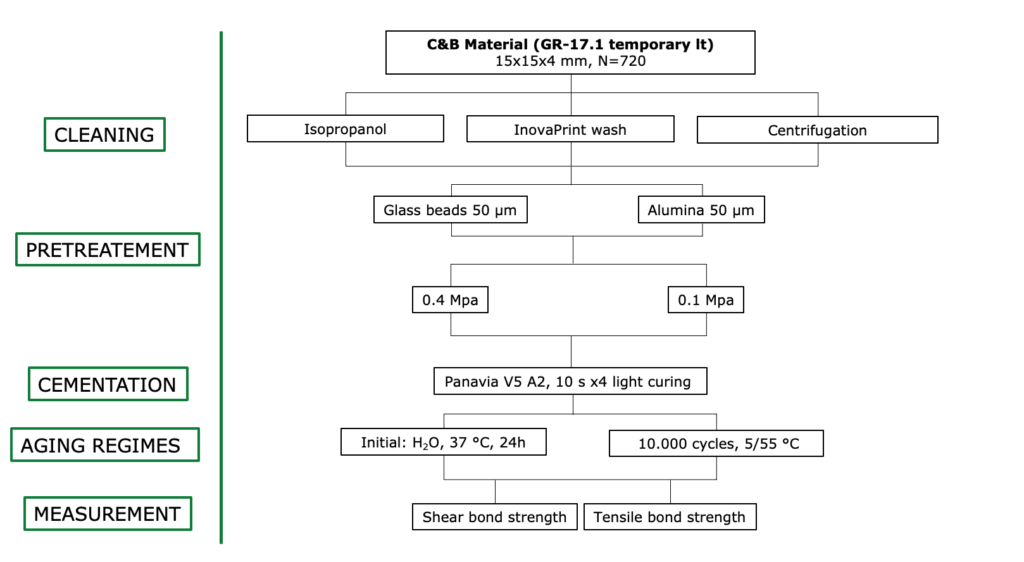

The aim of this in vitro study was to investigate whether the cleaning method and the mechanical pretreatment of the bonding surface influence the bond strength to a conventional luting composite. The effects of thermo-mechanical aging and the test method (shear or tensile bond strength) were also examined.

Fig. 1 Study design

Materials and methods

720 specimens (printodent GR-17.1 temporary lt, Pro3dure medical GmbH, Iserlohn) were 3D printed. Of the additively manufactured specimens, 360 were chemically cleaned using isopropanol (100%, SAP LP) or InovaPrint wash (HPdent GmbH) or excess monomer was removed by centrifugation (Fig. 2). Then air-particle abrasion followed using aluminum oxide particles (Strahlkorund, Orbis) or glass beads (Perlablast micro, Bego). The specimens were blasted for 10 s at 0.1 MPa or 0.4 MPa (Fig. 3). A conventional luting composite (Panavia V5, Kuraray) with a defined bonding surface was attached to the conditioned surfaces using prefabricated sleeves (Fig. 4).

Fig. 2-4 Specimens after centrifugation with excess resin. Air-abrasion with alumina. Specimen connected to luting composite.

In order to simulate the in vitro tests as close to the clinical practice as possible, half of the specimens in the present investigation were aged in a thermocycler (10 000 cycles, 5/55°C). The bond strength was calculated according to the following equation: Bond strength = load at fracture (N)/ bond area (mm2) = N/mm2

Fig. 6, 7 Tensile bond strength measurement and Shear bond strength measurement

Fig. 8 Boxplot: Shear bond strength

Fig. 9 Boxplot: Tensile bond strength

Results

The test method (shear or tensile bond strength) had the greatest effect on the bond strength. Higher values were obtained for shear strength than for tensile strength. A significant correlation between shear and tensile strength was observed. Furthermore, the cleaning method influenced the bond strength. Centrifugation increased the bond strength to the luting composite compared to chemical cleaning with isopropanol or InovaPrint wash. The air-abrasion parameters had less influence. A pressure of 0.4 MPa resulted in higher values than 0.1 MPa. Air-abrasion with alumina showed higher values than air-abrasion with glass beads. Artificial aging had the least effect on the bond strength. Here, higher bond values were observed after aging than after initial testing.

Conclusion

The results of this study show that the cleaning method and the mechanical pretreatment of the bonding surface influence the bond strength of 3D printed resins to a conventional luting composite. Regarding a luting strategy, air-abrasion with aluminium oxide at 0.4 MPa or additional conditioning with visio.link achieved the highest bond strengths, however, regardless of the chemical or mechanical cleaning method.